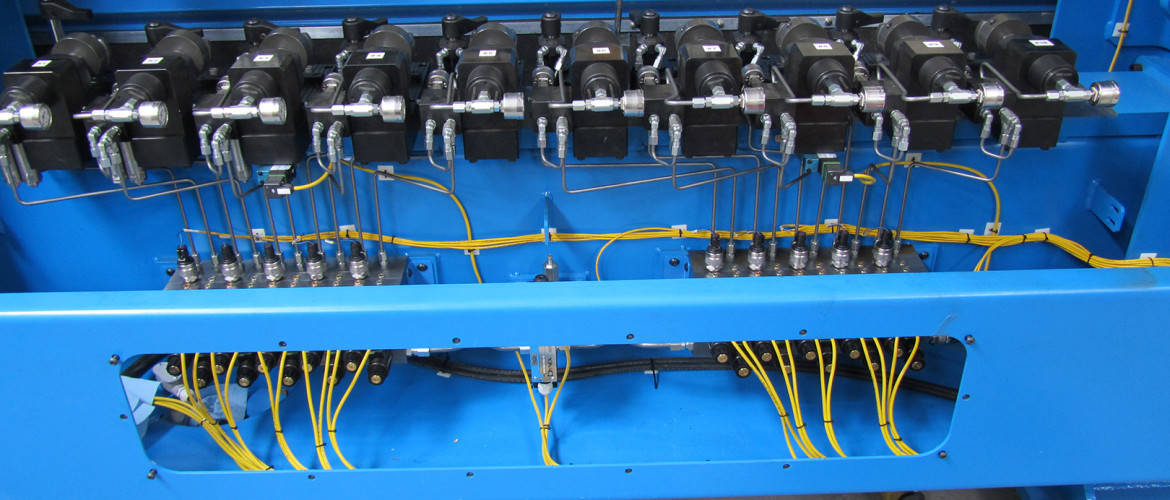

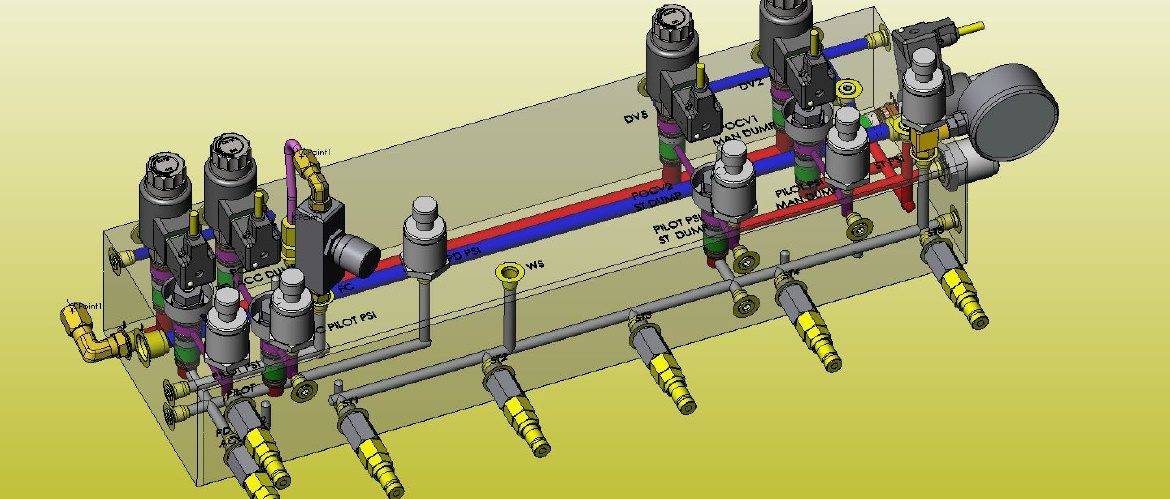

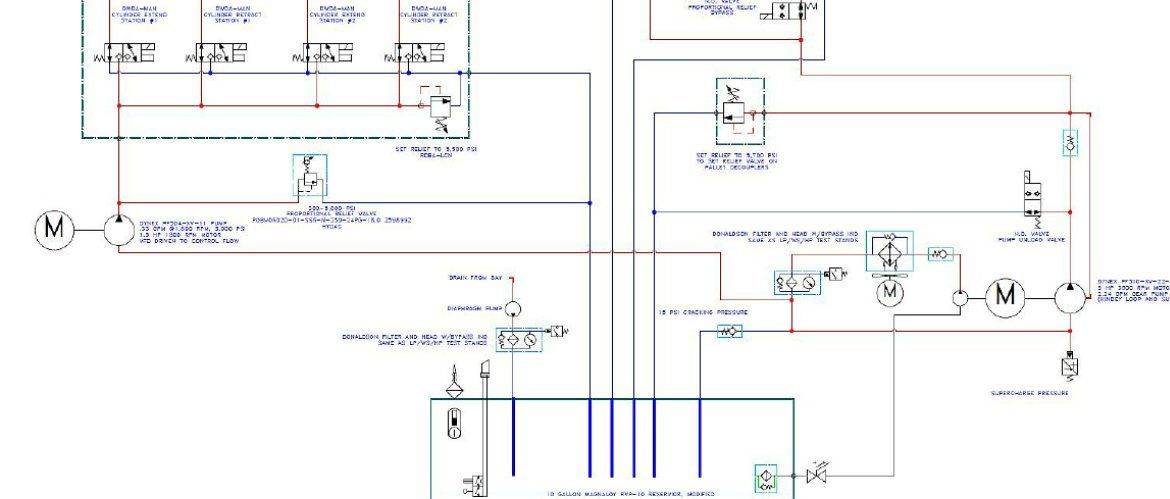

We specialize in accelerated life testing and functional testing of high pressure hydraulic devices. Our custom hydraulic test equipment typically has proportional flow and pressure (250-7,500 PSI) control as well as kidney loops to filter and cool the oil. The advanced control along with the use of proprietary hardware and software significantly reduce heat generation when using fixed displacement pumps.

Operating 24/7/365, the accelerated life test equipment has the ability to detect leaks and other fault conditions during testing and will automatically stop testing and notify the operator via email so that actions can be taken to correct the fault. Accelerated life testing equipment also incorporates redundant systems to minimize downtime during operation. Our test equipment can log data and parameters on the testing process, in real time, to a Microsoft SQL database. Testing reports can be viewed on a web browser to monitor the testing progress in real time.

We also engineer and manufacture custom hydraulic power units with fixed or variable displacement pumps up to 8,000 PSI.